mobile: 07885 881008 - 07841 470868

workshop: 01638 781 882

info@aquablast.uk.com

What is Ultrasonic Cleaning?

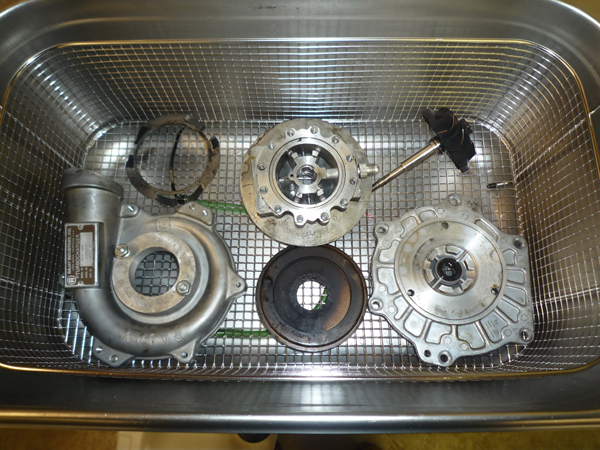

Another service we offer, which compliments Aqua Blasting, is Ultrasonic Cleaning.

Effective cleaning of components is an integral part of rebuilding or reconditioning an engine – Using an Ultrasonic cleaner can simplify and quicken this task while also providing improved results.

Older engines are prone to carbon build up which reduces the air flow through the engine and can cause running problems. However, there is a method of cleaning available that uses no harsh solvents, is fast and effective and requires only minimal amount of effot. This method is “Ultrasonic Cleaning”

The process of Ultrasonic Cleaning utilises high frequency sound waves which are radiated through a liquid medium – These sound waves are created by a number of transducers which are bonded to the base of the ultrasonic bath, as an electrical current is passed through the two transducer crystal rings they become agitated and vibrate at around 40,000 times a second. This vibration converts the electrical energy to sound energy which is then transferred through the base of the tank into liquid - As sound waves pass through the fluid microscopic bubbles form.

These bubbles continue to grow in size until they become unstable and cannot support their own density causing them to implode – this phenomenon known as cavitation, as these bubbles collapse the surrounding cleaning fluid rushes in to fill the gaps, which creats an action similar to that of a scrubbing brush, but thousands of times per second per cubic centimetre. It is this process which gives ultrasonic’s its powerful cleaning action and makes it the most effective method of removing contaminates from substrates or complex shapes. This process can be further intensified by adding cleaning detergent to the liquid – Ultrasonic detergents work on the simple principle as a normal household detergent by adding the loosening process.

In Layman’s term; If an item is submerged within the cleaning liquid any surface area which is in contact with the liquid medium will be exposed to cavitation, and therefore the cleaning action.

Ultrasonic cleaning represents a number of benefits over alternative methods which are available. People are being urged to move away from traditional methods which use solvents to remove baked on deposits as these are both hazardous to the environment and can be dangerous to those using them. Solvent based systems also take longer to remove deposits with items often needed to be soaked in the solution for a long period of time in order to brake down the baked on carbon and fuel residues.

The first benefit of using ultrasonic cleaning is the timescale for cleaning items.

Another major benefit of ultrasonic cleaning is its ability to reach hidden areas. As was previously stated, cavitation will occur anywhere where water particles can reach. This means that items such as cylinder heads, which have a number of internal channels, will be thoroughly cleaned throughout. The cleaning fluid will flood these channels enabling the scrubbing action to work in even the deepest and smallest spaces.

Although there are a number of sprays available which break down carbon deposits, they do not have the ability to completely remove carbon in the same way as an ultrasonic cleaner dose.

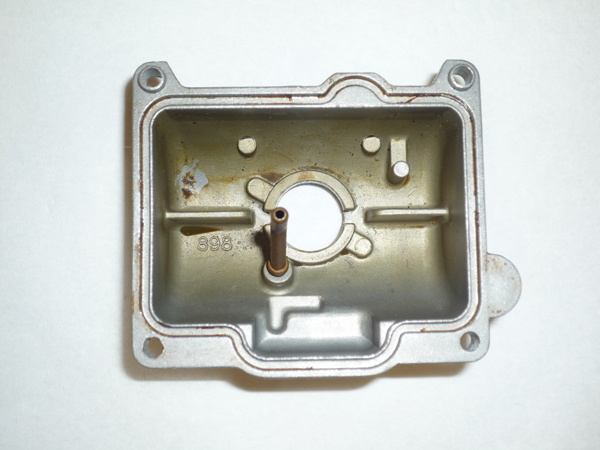

Ultrasonic cleaning is particularly useful for cleaning items such as injectors and carburettors. Cavitation will occur inside the injector nozzle or carburettor, breaking down debris that have built up inside, resulting in an injector which sprays out a perfectly conical shape fuel jet, and a carburettor which has maximum air/flow resulting in better fuel efficiency and soother torque and power curves.

Another common cleaned item id brake caliper – over time the seals on the pistons can become worn allowing dirt to lodge around the piston, when this occurs the caliper will require reconditioning, and an ultrasonic cleaner is the perfect method to use to ensure that no traces of grit are present prior to installing the new piston seal. It will also clean off carbon dust which has built up from the brake pads leaving the calliper in almost new condition. By removing the bleed nipple prior to placing the caliper in the tank and allowing the chamber to fill with water it will also mean that the internal areas will be cleaned – any debris which have become lodged in the inlet or within the chamber itself will be broken down and removed leaving the caliper free from potential blockage problems.

Ultrasonic Cleaning Prices

Single Carb - £40.00

Bank of 2 carbs - £50.00

Bank of 3 carbs - £60.00

Bank of 4 Carbs - £70.00

Bank of 6 carbs - £80.00